Det har gått mange år siden Alfa Romeo 8C Competizione gikk ut av produksjon. At denne eksklusive sportsbilen – bygget i Modena av Maserati – er en svært sjelden og sjeldent vakker rose, er de fleste enige om.

Men visste du at denne artikkelen faktisk er enda mer unik? Fordi den inneholder bilder av ikke mindre enn 2 stykk 8C fotografert på norsk jord (hva er muligheten for det?). Og fordi den er skrevet eksklusivt for Klubb Alfa Romeo Norge av han som hadde ansvaret for å utvikle bilen, nemlig Alfas tidligere produktutviklingssjef Claudio Marchesani. Her kommer hans beretning:

«It was the autumn of 2005 and I was closely involved in the start-up and marketing of some model versions of the Alfa Romeo 159, when – together with the top management – it was decided to start a new project to support and revitalize (at that time) the Alfa Romeo brand.

The decision goes through the manufacturing of an elite car that would be the new Alfa Romeo flagship. It was to carry on the «road» 8C's Concept, able to show to the world, for style and driving pleasure, the excellence and distinctiveness of Alfa Romeo sportiness.

Through the perfect combination of superb and unique style and exceptional driving sensations, we wanted to show the public the ability of our company to integrate rational and emotional elements typical of the brand in a unique object with which to grasp the attention of connoisseurs and collectors all around the world.

In particular, the goal that we gave, was to summarize in this exclusive and unique object the DNA of Alfa Romeo:

Tradition, italian spirit, passion, engineering, performance and technological innovation.

Meetings at the Centro Stile

It was made up as a team in which I had the role of the Product Development Manager. It was months of hard work with continuous meetings at the Centro Stile, in Arese and Turin, on the track at Balocco and then at the Maserati factory in Modena where the team settled for a few months until the industrialization and commercialization of the product.

We also decided to show up the model between a world premiere to the 2006 Paris Motor Show (which then I will tell you a little episode) and start the manufacturing over the next year.

The first decisions were to define the marketing aspects such as, for example, what are the profiles of potential buyers of the 8C in terms of lifestyle, social and professional status and vehicle usage, what are the 8C's main competitors, which other vehicles could a potential buyer consider as an alternative to the 8C, to define market price positioning, to set the number of cars to be produced…

500 pieces

Our goal was to ensure the exclusivity of the product where the buyer could enjoy the pleasure of owning an almost unique product of its kind.

The Limited Edition of 500 pieces represented, in our view, a production volume with a great value for those were seeking true collector cars.

It was also crucial to ensure the craftsmanship and the highest quality of this product, therefore this number represented the perfect quantity to achieve standards of absolute importance.

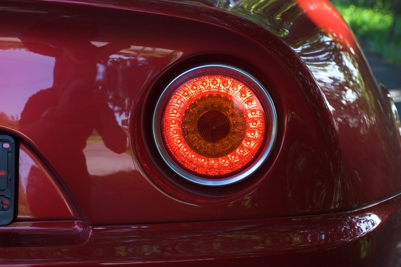

The style of the exterior was a real masterpiece of purity of lines, integration and reminder to elements and shapes presented on cars of the past – glorious Alfas like the 33 Stradale and the Giulia TZ – it suffered few adjustments compared to the Concept, mainly aimed at allowing aerodynamic improvements and obtain downforce at high speeds.

Attention to detail

Any other component, especially for the interiors, had to be stylistically coherent with the other: Shapes, rays, profiles and curvatures were engineered and designed to provide a coherent reading language between them.

Nothing was left to mere improvisation, even less the use of carry-over components without proper customization.

Every single detail, each component, each function had to be recognizable as the result of a careful and meticulous analysis. The attention to detail and obsessive attention with which we realized and put together the different parts, were later recognized by the international press and by the customers that quickly ran out all the 500 cars available.

Constant search for materials

It was decided, in order to ensure at the same time qualities such as lightness, strength stiffness and low centre of gravity, to realize body, dashboard and panels in carbon fiber; composite material instead for bumpers, seats and minor parts.

It's important to note that the dashboard, in addition to being made of carbon fiber, had a style that reproducing the profile of wing surfaces.

Aluminum was chosen for the realization of the main tabs and internal finishes, including for example the big handle on the central tunnel, the bolsters lights command, the switches, and the closing of the door handle.

It should be noted that it was high-value pieces, which were obtained with a machining process directly from a solid piece.

Regarding the definition of the contents of the interiors, what I remember was the constant search for materials that could transmit sensations of essentiality and structural lightness.

We were able to identify and to integrate technical materials such as carbon fiber and aluminum and leather and braided of natural fibers, always trying to maintain the proper balance between form and function.

The Alfa spirit of driving

In order to have the Alfa Romeo driving pleasure at its best expression, able of offer sensations of real and pure sportive car but also suitable for relaxed usage, we proceeded to develop and customize the Alfa spirit of driving, acting on handling, gas response, brakes and steering response, inlet and exhaust sound.

The eight-cylinder engine naturally aspirated was brought to 450 horsepower.

It received an effective fine-tuning of the power and torque curve in order to offer great usability and fluidity in every situation of use. The result was an extraordinary performance, available power and smooth running in all situations: From city traffic to the race track!

The architecture was of the type transaxle, with rigid connection between the front and rear gearbox motor. It allowed an optimum allocation of weights and masses that were arranged with all the interior of the wheel axis, minimising the polar moment, for greater speed response of the vehicle.

The front and rear suspensions, double wishbone with arms and aluminum parts, together with direct steering, brakes with ventilated discs of large diameter and fixed callipers, the tires specifically developed with the supplier, ensured handling inimitable with immediate answers to the directional stresses and excellent traction.

2006 Paris Motor Show

And now, as I already hinted, I will report a «funny» episode that happened at the time of first press international presentation, at the 2006 Paris Motor Show.

We worked late during the night before the opening to prepare the car, checking the correct functionality of the parts interested to the presentation. When I closed the driver's door, one sheet metal edge came in contact with the window causing a small but visible crack in the bottom of it.

Panic and general despair just a few hours before the event! How, how to fix it?

Immediate consultations with the workshop in Italy for the availability of spare parts, impossible to get in a few hours. We decided to lower both crystals, enough to hide the crack and deactivated the switches, proceeding in the following days to the crystal replacement.

The presentation was a great success and I was largely repaid of the sleepless night. Within a couple of months we ran out the presale of the Limited Edition with great satisfaction for the whole team and our company.»

______________________

Hovedtekst: CLAUDIO MARCHESANI

Innledning: CHRISTIAN JARRE

Foto: ANDERS BULL

______________________

Fra Alfanytt #2/2017 – medlemsblad for Klubb Alfa Romeo Norge. Gjenbruk er kun tillatt med Alfanytt-redaktørens skriftlige samtykke.